Routine maintenance

About this topic

This topic provides recommendations for maintaining the BenchCel Microplate Handler.

Cleaning up spills and periodic cleaning

In general, practice good housekeeping by cleaning up spills and routinely cleaning after using the BenchCel Microplate Handler.

Use a clean soft cloth or laboratory wipes to clean up spills on any part of the device immediately after a protocol run.

Clean the BenchCel device weekly or as needed. Use standard laboratory wipes and a mild detergent or isopropyl alcohol to clean the exterior painted white surfaces and the metal surfaces of dust, grime, chemical deposits, and other debris.

Also see Cleaning up after a protocol run.

Monthly inspection and maintenance

Every month, check the following:

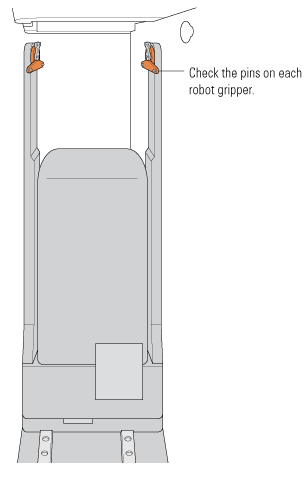

• Robot gripper pins. Make sure they are not too dull to grip the microplates. If the pins have become dull, contact Agilent Technical Support to replace them.

Figure Robot head (side view)

|

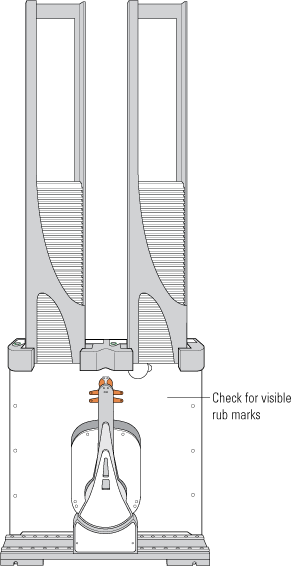

• Moving parts. Ensure they are not rubbing against each other. Look for rub marks or noises that might indicate rubbing. If you see rub marks, contact Agilent Technical Support.

|

• Air-supply tubing. Verify that the tubing is in good shape and there are no leaks. Replace the broken tubing if necessary.

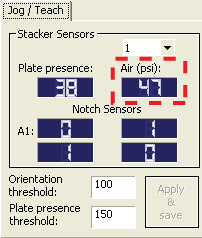

• Stacker gripper pressure. Make sure the pressure is set correctly. On the Controls page in BenchCel Diagnostics, click the Jog/Teach tab, and check the Air reading.

|

Integrated device

For routine maintenance of the devices integrated with the BenchCel device, see the user documentation for the corresponding device.

Related information

For information about... | See... |

|---|---|

Cleanup procedure after every protocol run | |

Air source requirements | |

Checking and adjusting the stacker gripper pressure (internal air pressure) |