Labware considerations

About this topic

This topic provides guidelines for selecting automation-ready labware for use in the BenchCel Microplate Handler.

Acceptable microplates

The BenchCel device is designed to handle labware that comply with the standards ANSI/SLAS 1-2004 (R2012) through ANSI/SLAS 4-2004 (R2012). For use of nonconforming labware, contact Agilent Technical Support.

The BenchCel device uses gripping mechanisms to hold microplates securely and repeatably in the labware rack and in the robot arms. The BenchCel device typically holds the microplates halfway between the top of the microplate and the top of the microplate skirt (5 to 10 mm above the bottom of the microplate).

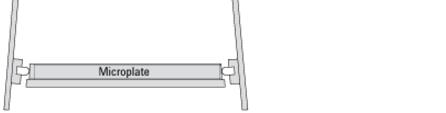

In the following figure, notice the gripper-microplate contact point.

Figure Labware rack closeup view showing microplate held by the stacker grippers

|

Lidded microplates

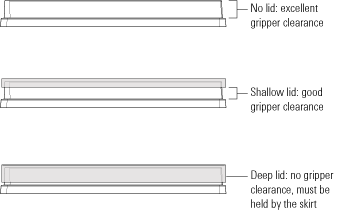

Microplates that do not have lids or have shallow lids (lids that do not reach the microplate skirt) provide enough clearance to allow secure and repeatable gripping. Microplates with deeper lids can be more challenging, because the microplate must be held by the skirt. If the skirt is too flexible, the stacker grippers will bend the skirt. The bent skirt can grip the microplate lid stacked beneath, inadvertently removing the lid.

Note: Some labware vendors might offer alternative lids that are shallower. Contact the vendor for details.

Figure Lidded microplate examples

|

Challenging microplate characteristics

Microplates that have the following characteristics might require additional setup time to ensure repeatable performance for the BenchCel device:

• Microplate material. Although you can adjust the robot grip distance to compensate for a microplate’s flexibility, some microplates are too soft and tend to bend in the robot grippers or become warped after thermal cycling. (for example, low-profile polypropylene PCR microplates).

• Manufacturing variance. Gross variations in microplate dimensions can reduce repeatability of secure gripping. In addition, because the BenchCel device uses reflected light to sense microplate presence and orientation, variations in the reflective properties of the microplates can affect optimal operation.

• Microplate design. Some microplates have special features specifically designed for particular instruments but are not optimized for the BenchCel device.

• Thermal cycling effects. Microplates that have been through thermal cycling might become warped.

• Tall labware. Especially tall tube racks and tip boxes that are taller than 65 mm might pose challenges in the BenchCel device. Contact Agilent Technical Support about acceptable tall labware.

• Extra long lid. Some microplates that have lids that extend past the microplate skirt tend to pose challenges for the BenchCel device. Contact Agilent Technical Support for guidance.

Related information

For more information about… | See… |

|---|---|

Defining labware in the software | VWorks Automation Control Setup Guide |

Location of plate-orientation sensors | |

How the plate-orientation sensors work | |

BenchCel Microplate Handler features | |

Safety information | |

Installation requirements |