Hardware overview

About this topic

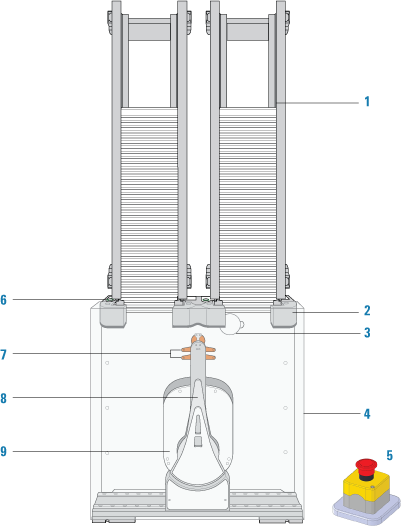

This topic describes the hardware features of the BenchCel device. Note that the figures in this topic show a BenchCel 2R device with two stackers that support two labware racks. All the major components and functions are the same for the BenchCel 4R (four stackers) and BenchCel 6R (six stackers).

Front view

|

Item | Feature | Description |

|---|---|---|

1 | Labware rack | The accessory that stores labware to be processed in a run. For details, see Labware racks. |

2 | Stacker head | The structure at which: • A labware rack is loaded. Two sensors inside of each stacker head detect the presence of the racks. • A microplate is checked for type and orientation using a plate-presence sensor and four plate-orientation sensors. • A microplate is lowered into the stacker grippers to begin a run. See Stacker head for the location and detailed descriptions of the sensors. |

3 | Air pressure regulator | The knob that you turn to adjust the air pressure inside the device. Compressed air is used to move components inside the stacker heads. Each regulator controls the air pressure to the two adjacent stacker heads. For details, see Adjusting the stacker gripper pressure. |

4 | Safety shield | The clear panel that is installed on the front of the BenchCel device to prevent access while it is in operation. |

5 | Pendant | The component that is part of the safety interlock circuit, which must be closed for the BenchCel device to operate. Pressing the raised button on the pendant interrupts the safety circuit and disables the robot motors. Use this method of stopping the robot for emergencies only. |

6 | Rack-release button | The button that unlocks the rack for removal. The rack-release button at the top of each stacker head displays different colors to indicate the state of the stacker head: • Green. The labware rack is installed correctly on the BenchCel device and the microplates are unloaded. The stack of microplates are ready for processing or you can unlock and remove the labware rack. • Flashing green. The labware rack is unlocked and can be removed. • Blue. The stack of microplates is loaded. You cannot unlock and remove the labware rack. • Red. The clamps are open without a rack installed. Do not install a rack until the clamps are closed. |

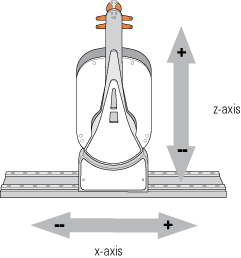

7 | Robot head | The component that moves horizontally along the x-axis and vertically along the z-axis.  |

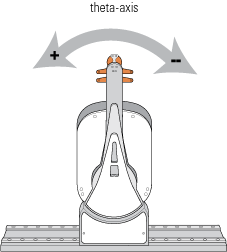

8 | Robot arms | Two parallel structures that are attached to and rotate about the robot head along the theta-axis.  |

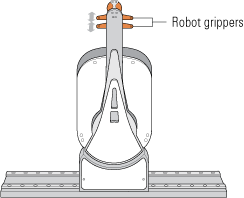

9 | Robot grippers | The structures inside the robot arms that close and open to hold and release a microplate. Using the provided software, you can adjust the distance between the grippers to hold a microplate loosely or tightly.  |

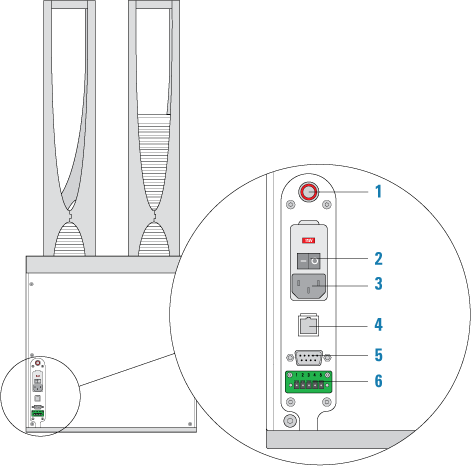

Back view

|

Item | Feature | Description |

|---|---|---|

1 | Air-input fitting | Connects the air tubing to the BenchCel device. Compressed air is used to actuate components inside the stacker head. |

2 | Power switch | Turns on or off the power to the BenchCel device. |

3 | AC power entry | Connects the power cord to the BenchCel device. |

4 | Ethernet port | Connects the Ethernet cable from the controlling computer to the BenchCel device to allow communication between the computer and the device. Use this port as an alternative to the serial connection. |

5 | Serial port | Connects the serial cable from the controlling computer to the BenchCel device to allow communication between the computer and the device. Use this port as an alternative to the Ethernet connection. |

6 | Pendant port | Connects the emergency-stop pendant to the safety interlock circuit. The connection is made either directly or through an emergency-stop control, such as the Robot Disable Hub. |

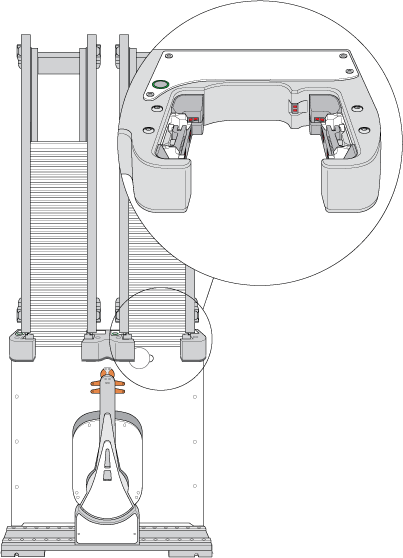

Stacker head

At the top of the BenchCel device are stacker heads that contain infrared sensors and mechanical components that load and unload microplates during operation.

|

The following table lists and describes the various components inside the stacker head.

Feature | Description |

|---|---|

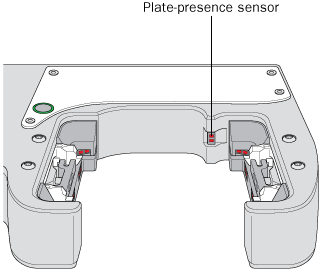

Plate-presence sensor | Detects the presence of a microplate in the stack. One plate-presence sensor is on the back wall of each stacker head.  |

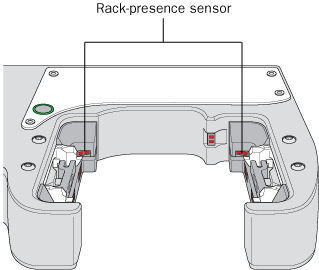

Rack-presence sensors | Detect the presence of labware racks. Two rack sensors are on the back wall of each stacker head.  |

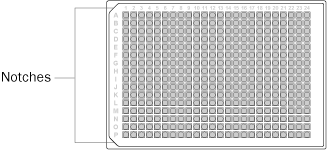

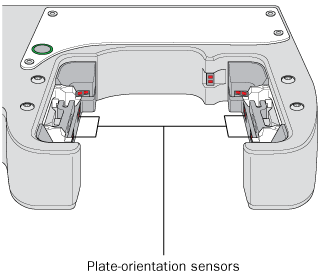

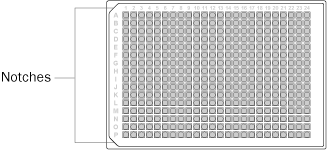

Plate-orientation sensors | Detect the presence of notches in microplates. Four sensors are in the inside corners of each stacker head. For details of how the sensors work, see Setting sensor thresholds.   |

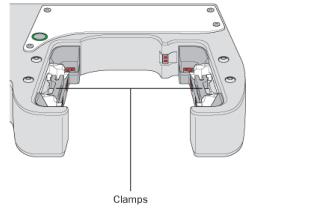

Clamps | Close and open the grippers at the bottom of the labware rack to hold and release microplates during loading, unloading, downstacking, and upstacking processes. Two clamps are inside each stacker head. Compressed air is used to open and close the clamps.   |

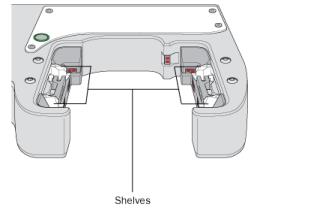

Shelves | Provide leveling surfaces for the microplates, thus ensuring accurate robot gripping, during the downstacking process. Two shelves (four leveling surfaces) are inside each stacker head. Compressed air is used to move the shelves.  |

Labware racks

The labware racks are available in two models:

• Front-load rack in 250-mm and 660-mm sizes

• Top-load rack in 660-mm and 860-mm sizes

Both rack models have the following basic components.

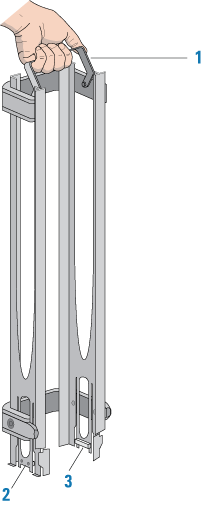

Figure Front-load rack components

|

Item | Name | Description |

|---|---|---|

1 | Carrying handle | The top-load and front-load racks have fold-down carrying handles. |

2 | Tabs | A pair of vertical tabs are located at the bottom on the rack sides. The tabs insert into slots on the device when you mount the rack onto the device. |

3 | Stacker grippers | A gripper is located on the interior bottom of each tab. The pair of grippers hold a microplate during the labware loading, unloading, downstacking, and upstacking processes. A clamp in the device opens and closes the grippers. |

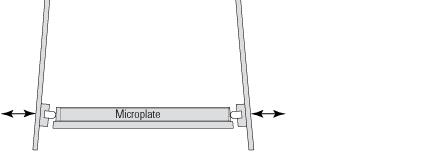

The following figure shows a closeup view of a labware rack, with the stacker grippers holding a microplate. The front wall of the rack is not shown to reveal the stacker grippers that are hidden from view.

Figure Labware rack closeup view showing microplate held by the stacker grippers

|

Related information

For more information about… | See… |

|---|---|

Automation-ready labware | |

Software that controls the BenchCel Microplate Handler | |

Safety information | |

Installation requirements |