Laboratory requirements

About this topic

This topic describes the requirements for the site where you plan to install the Microplate Labeler. The topics are:

Laboratory space requirements

General bench requirements

Make sure the bench for the Microplate Labeler has the following:

• Sufficient space to accommodate the Microplate Labeler, computer, monitor, and accessories

• Sufficient clearance:

– On the back of the device to access power, communication, and air tubing connections

– Above the printer to open the printer cover

– On the side of the printer to replace the label and ribbon rolls

Note: The snap-off cover can be removed from the printer if the device is operated within an enclosure where no corrosive chemicals or gases are present.

• A fixed bench (without wheels) that can support the weight of the Microplate Labeler without excessive shaking or movement

• Proper height for any operator to comfortably operate the Microplate Labeler

Physical specifications

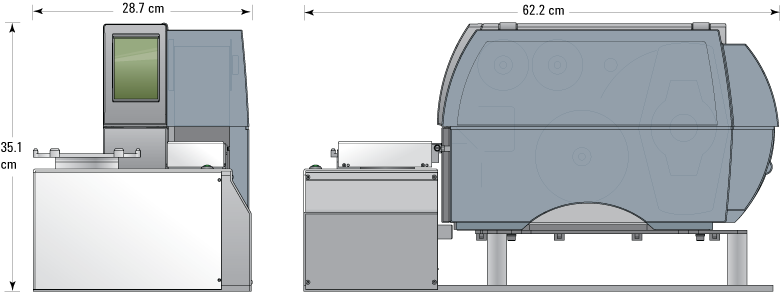

Dimension | Value |

|---|---|

Width | 28.7 cm (11.3 in) |

Height | 35.1 cm (13.8 in) |

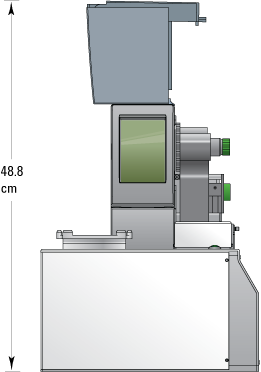

Height with printer cover opened | 48.8 cm (19.2 in) |

Depth | 62.2 cm (24.5 in) |

Weight | 21 kg (47 lbs) |

Note: Measurements do not include the cables or the computer.

Figure Dimensions (front and side views)

|

Figure Microplate Labeler with printer cover open (front view)

|

Electrical requirements

The Microplate Labeler device has the following power requirements:

Utility | Requirement |

|---|---|

Electrical | 100–240~, 50/60 Hz, 2.75 A |

Fuse | Two 3 A, 0.25 x 1.25 in (6.35 x 31.75 mm), fast acting |

Compressed air requirements

The Microplate Labeler requires the use of clean, dry, compressed air to move the pneumatic components. The compressed air can be from the following sources:

• Centralized source (laboratory)

• Compressed-air cylinders

• Portable pumps

The Microplate Labeler has the following minimum compressed-air requirements:

Requirement | Value |

|---|---|

Quality | Clean, dry, compressed |

Flow rate and pressure | 1.2 Lps at 0.55 MPa (2.5 cfm at 80 psi) |

Environmental requirements

The Microplate Labeler is for indoor use only. The following table lists the operating specifications for the device.

Operating | Specification |

|---|---|

Pollution degree | 2 |

Installation category | II |

Temperature | 4–40 °C |

Humidity | 10–90% RH, non-condensing |

Altitude | 1–2000 m |

Make sure the Microplate Labeler is located away from moisture (sprays of water or mists).

The Microplate Labeler uses adhesive labels that are compatible with most common laboratory solvents, including DMSO and alcohols. The labels can withstand exposure to temperatures of –80 °C to 100 °C.

Computer requirements

The requirements of the controlling computer depend on the lab automation software you are using.

• VWorks software computer requirements. See the VWorks software release notes or the Automation Solutions Knowledge Base at www.agilent.com/chem/askb.

• Third-party automation software requirements. See the user documentation supplied with the product.

Consumables

The Microplate Labeler uses thermal transfer ribbon and adhesive labels. Your shipment includes the Agilent Media Kit, which contains a one-to-one quantity of the ribbon and labels so that you can replace them at the same time. The kit also contains a pen for cleaning the printhead and an empty spool to take up the used ribbon.

Related topics

For information about... | See... |

|---|---|

How to install the device | |

How to install the software | Software release notes |

Safety | |

How to report a problem |