Emergency stops

The BenchCel Microplate Handler is equipped with an interlock circuit and emergency-stop pendant.

Stopping in an emergency

To perform an emergency stop:

Press the red button on the pendant. The safety interlock circuit is interrupted, disabling the robot motors. The BenchCel Microplate Handler operation stops.

|

Recovering from an emergency stop

After you press the button on the emergency-stop pendant, the robot stops. One of the following occurs:

• If you stopped a protocol run, a dialog box opens in the VWorks software.

• If you stopped the robot while diagnosing problems in BenchCel Diagnostics, a motor-disable message appears on the screen.

Use the following procedure to recover in either case.

To recover the BenchCel device after an emergency stop:

1 If the robot dropped labware before or during the emergency stop, remove labware that was dropped. Also remove labware at teachpoints or other locations.

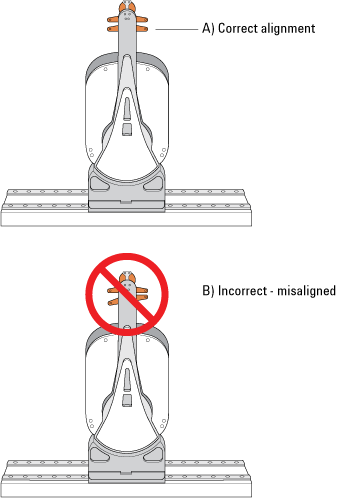

2 If the BenchCel robot attempted to place labware at a location that was not free, a collision might have occurred resulting in misalignment of the robot gripper. Check the robot gripper alignment:

a Move the robot arms so that they are perpendicular to the x-axis.

b Make sure the bottom of the robot gripper pads are perpendicular to the robot arms. If they are not, contact Agilent Technical Support.

Figure Gripper alignment: (A) correct alignment, and (B) incorrect alignment

|

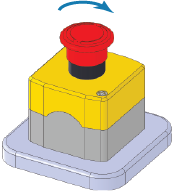

3 To re-enable the motors:

a At the emergency-stop pendant, turn the button clockwise to release it.

|

b In the VWorks software message dialog box, select an appropriate option to continue:

Selection | Description |

|---|---|

Diagnostics | Opens the BenchCel Diagnostics dialog box. See step 4. Note: This selection is available only when you are in the middle of a protocol run and not while you are in BenchCel Diagnostics. |

Retry | Attempts to restart the current command or task in the run. |

Ignore and continue | Ignores the current command or task and continues to the next command or task in the protocol sequence. |

Abort | Aborts the current command or task in the run. Select Abort if you have determined that the protocol run is not recoverable. |

For a full description of the selections, see the VWorks Automation Control User Guide.

4 Optional. In BenchCel Diagnostics, use the available commands to manually move the robot or other components, including:

• Release the microplate that the robot is currently holding.

• Upstack the microplate that the robot is currently holding.

• Replace the lid on the microplate.

• Home the robot.

• Verify teachpoints.

For details, see Diagnostic tools.

If a physical crash occurred, always start BenchCel Diagnostics to home the robot and verify teachpoints.

Related information

For information about… | See… |

|---|---|

Pausing and resuming protocol runs | VWorks Automation Control User Guide |

Using commands in BenchCel Diagnostics | |

Complete list of available commands in BenchCel Diagnostics | |

Reporting a problem |