Setting Stacker properties

When to set Stacker properties

If you are using a BenchCel Microplate Handler in your automation system, you must set the properties in the Stacker sub-tab of the Labware Editor.

Before you start

• You must be logged in as an administrator or technician to perform this procedure.

• You must first create an entry for the labware.

• Make sure you have read the sections of the BenchCel Microplate Handler User Guide that describe the location and function of the stacker sensors.

Note: This VWorks version does not support the Labware Stacker.

• VWorks Plus only. Each labware entry is a record of interest that transitions through development states. A VWorks technician or administrator can edit labware entries that are In Development or In Validation. The parameter settings in the Labware Entries tab are unavailable if the labware entry is Released.

Setting properties

To set stacker properties:

1 Open the Labware Editor.

2 In the Labware Entries tab, click the Stacker sub-tab.

3 Enter the values for the available properties according to the labware you are defining.

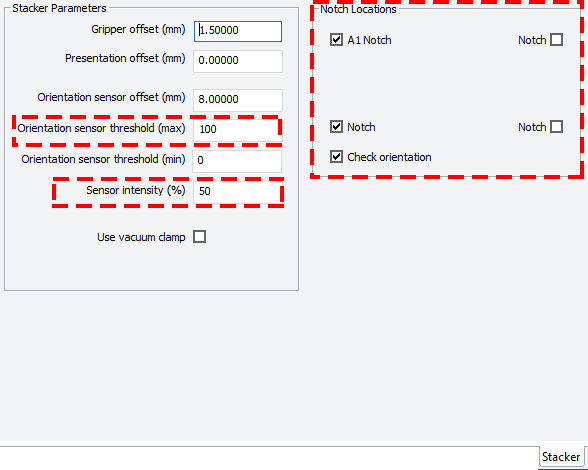

Set only the maximum orientation sensor threshold, sensor intensity, and notch locations. The other settings are not used.

Figure Properties required for the BenchCel Microplate Handler

|

The following table provides descriptions of each parameter required for the BenchCel Microplate Handler.

Parameter | Description |

|---|---|

Stacker Parameters | |

Orientation sensor threshold (max) | Specifies the highest value that an orientation sensor can register when sensing a notch. Any sensor reading above this value indicates that a solid microplate wall is present. Any sensor value below this threshold indicates that either a notch, or no microplate is present. If the stacker does not sense a notch when it should, you will get a “wrong plate type” or a “plate rotated 180 degrees” error message. Adjust the sensor threshold value. The maximum value is 255. |

Sensor intensity | Sets the percentage of maximum sensor intensity for all sensors. If the sensor intensity is set too low, a microplate will not be detected even though one is present. If it is set too high, the sensors might become saturated, causing failure to detect the orientation of a microplate. This parameter adjusts for the fact that clear, black, and white microplates reflect light differently. For example, white microplates generally reflect more light so the sensor intensity should be set lower. |

Notch Locations | |

Check orientation | Turns on microplate-orientation checking based on the selected notch locations for your microplate. The notch locations are ignored when this check box is cleared. |

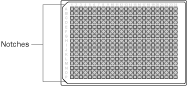

Notch location check boxes | Select the corresponding notch or notches for your microplate. For BenchCel Microplate Handlers, the A1 well of the microplate is positioned in the far, left corner as you face the front of the BenchCel Microplate Handler.  |

Related information

For information about... | See... |

|---|---|

Workflow for adding labware to the Labware Editor | |

Opening the Labware Editor | |

Using the Labware Editor |