Creating a liquid class

About this topic

This topic describes how to create a liquid class using the Liquid Library Editor.

You must be logged in as a VWorks technician or administrator to perform this procedure.

Liquid compatibility

Agilent Automation Solutions product surfaces are designed to be compatible with small volumes of aqueous solutions, common biological buffers, solvents, and common reducing agents. You can find a list of compatible chemicals in the Automation Solutions Products General Safety Guide.

Procedure

VWorks Plus only. Each liquid class is a record of interest that transitions through development states. A VWorks technician or administrator can edit liquid classes that are In Development or In Validation. If the liquid class is In Development, an administrator can delete it in the Liquid Library Editor.

To create a liquid class:

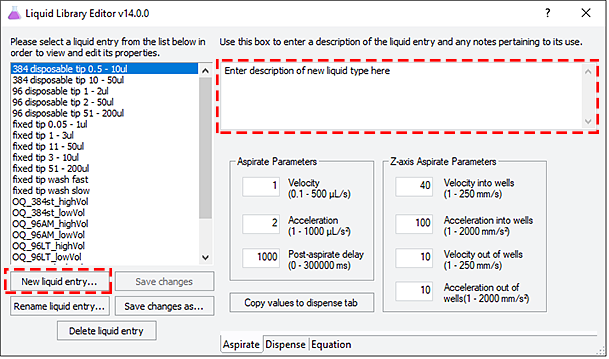

1 Open the Liquid Library Editor.

2 Click New liquid entry.

|

3 In the New Liquid Entry dialog box, type a name for the liquid class and click OK.

4 Optional. In the box at the top right of the Liquid Library Editor window, type a note describing the entry for your records.

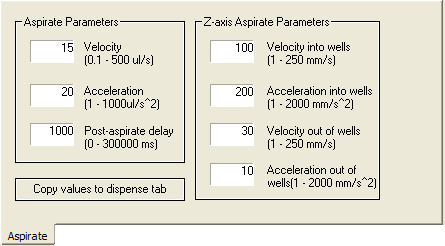

5 On the Aspirate tab, type the values for the following aspirate parameters.

|

Note: The upper limits for some of the parameters might not be achievable for the device you are using.

The Bravo Platform has the following upper limits:

Parameter | Upper limit |

|---|---|

Velocity into wells | 125 mm/s |

Acceleration into wells | 375 mm/s2 |

Velocity out of wells | 125 mm/s |

Acceleration out of wells | 375 mm/s2 |

The following table describes the aspirate parameters.

Aspirate | Definition |

|---|---|

Velocity (µL/s) | Specifies the speed of the aspiration stroke. |

Acceleration (µL/s2) | Specifies acceleration during the aspiration stroke. |

Post-aspirate delay (ms) | Specifies the time the pipettor waits after aspiration is complete before moving the tips out of the wells. |

Z-axis velocity into wells (mm/s) | Specifies how fast the pipettor moves as the tips enter the wells. |

Z-axis acceleration into wells (mm/s2) | Specifies the acceleration of the pipettor as the tips move into the wells. |

Z-axis velocity out of wells (mm/s) | Specifies how fast the tips leave the wells. |

Z-axis acceleration out of wells (mm/s2) | Specifies the acceleration of the pipettor as the tips move out of the wells. |

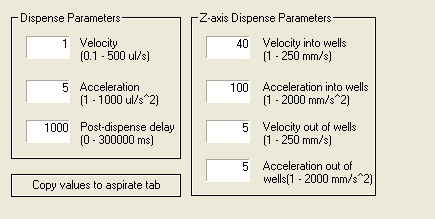

6 Click the Dispense tab and enter values for the dispense properties.

|

Note: The upper limits for some of the parameters might not be achievable for the device you are using.

The Bravo Platform has the following upper limits:

Parameter | Upper limit |

|---|---|

Velocity into wells | 125 mm/s |

Acceleration into wells | 375 mm/s2 |

Velocity out of wells | 125 mm/s |

Acceleration out of wells | 375 mm/s2 |

The following table describes the dispense parameters.

Dispense | Definition |

|---|---|

Velocity | Specifies the maximum speed of the dispensing stroke, in microliters per second. |

Acceleration | Specifies acceleration during the dispensing stroke, in microliters per second squared. |

Post-dispense delay | Specifies the time the pipettor waits after the dispense stroke before moving the tips out of the wells, in milliseconds. |

Z-axis velocity into wells | Specifies how fast the pipettor moves as the tips enter the wells, in millimeters per second. |

Z-axis acceleration into wells | Specifies the acceleration of the pipettor as the tips enter the wells, in milliliters per second squared. |

Z-axis velocity out of wells | Specifies how fast the pipettor moves as the tips leave the wells, in millimeters per second. |

Z-axis acceleration out of wells | Specifies the acceleration of the pipettor as the tips leave the wells, in millimeters per second squared. |

7 Click Save changes.

8 VWorks Plus only. If an audit trail is being logged, the Audit Comment dialog box opens. Select or type the audit comment, and then click OK.

Related information

For information about... | See... |

|---|---|

Liquid classes | |

Opening the Liquid Library Editor | |

Calibrating your pipettor | |

Audit trails and records of interest |