Upstack

Description

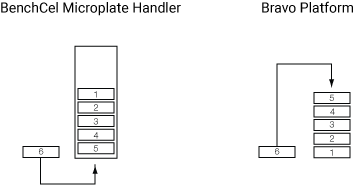

The Upstack task ( ) moves labware as follows:

) moves labware as follows:

• Into the bottom of stacking devices such as the BenchCel Microplate Handler

• Onto the top of a stack of labware at a Bravo deck location

|

For example, you can use the Upstack task to move a microplate from a platepad into the BenchCel Microplate Handler.

You can use a single Upstack task to move labware into multiple stacking devices. For example, if three stackers are available, the upstack task can dynamically move microplates into any of the three stackers.

Task is available for... | Task is available in... |

|---|---|

BenchCel Microplate Handler | Main Protocol |

Bravo Platform | Main Protocol, Bravo Subprocess |

Requirements

Bravo Platform

To use the Upstack task in a Bravo Subprocess, you must:

• Select the desired stacking options in the Bravo profile.

• Specify the maximum stack height in the Bravo deck location properties area.

• Add a Scan Stack task for each Upstack task.

Task parameters

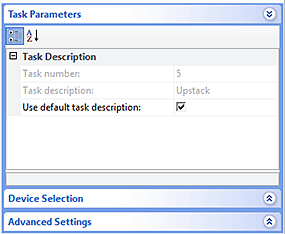

After adding the Upstack task at the desired point in the protocol, set the following parameters in the Task Parameters area:

|

Parameter | Description |

|---|---|

Task number | The number that indicates the position of the task in the protocol. |

Task description | The description of the task. |

Use default task description | The option to use the default task description or provide your own description for the task. Select the check box to use the default description. Clear the check box to provide your own description. |

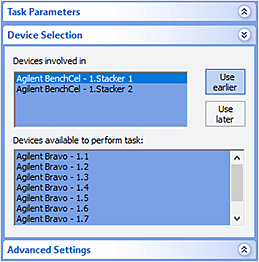

Device selection

You must select a device for Upstack tasks. If you have multiple devices of the same type, you can prioritize the list of devices for the task. If the first device in the list is busy, the software will automatically use the next device in the list. If all of the devices in the list are busy, the task that needs the device will wait until one becomes available.

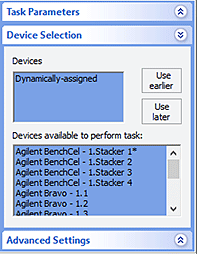

After adding the Upstack task at the desired point in the protocol, select the task, and then click Device Selection in the Task Parameters area.

To select a device for the task:

1 Double-click a device or deck location in the Devices available to perform task area to add it to the Devices involved in task area.

Note: If you want the software to dynamically move labware to available stackers, double-click Dynamically assigned in the Devices available to perform task area. You can check the run log to determine the location of the labware in the various stackers.

2 To prioritize its use, select the device in the Devices involved in task area, and then click User earlier or Use later. The devices that are higher in the list are favored by the software scheduler during the protocol run.

|

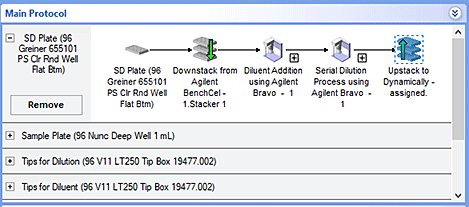

Example 1: Dynamically upstack microplates into a stacking device

Goal

After the Destination Plate is finished with the Bravo liquid-handling process, upstack it to any available stacker.

Implementation

Add a Upstack task after the Bravo Subprocess task that contains the liquid-handling sub-routine.

|

The device selection is Dynamically assigned:

|

Example 2: Stacking on the Bravo Platform

Goal

Downstack microplates for liquid-handling process, then upstack them.

Implementation

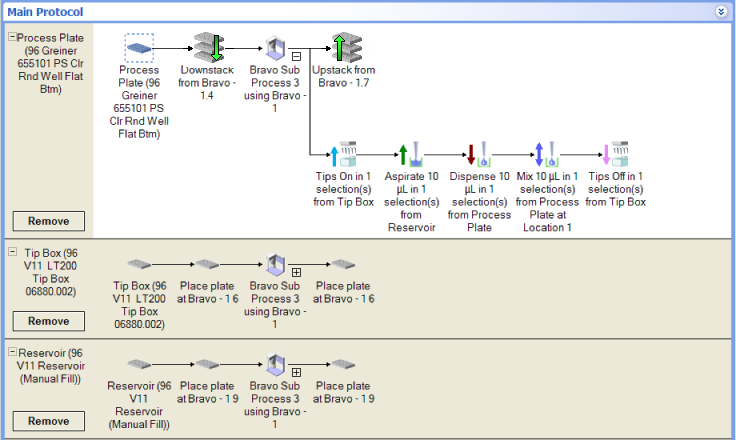

The protocol is set up as follows:

• A stack of microplates (Process Plates) is at deck location 4.

• A tip box (Tip Box) is configured at deck location 6.

• A Manual Fill Reservoir (Reservoir) is configured at deck location 9.

• The Startup Protocol (not shown) contains Scan Stack tasks for deck locations 4 (where the stack starts) and 7 (where the stack will end up after upstacking).

|

The protocol performs the following:

1 The robot scans deck location 4 to confirm the presence of the stack and determines the number of microplates. (The Scan Stack task in the Startup Protocol, not shown, performs this task.)

2 The robot scans deck location 7 to confirm the absence of labware. (The Scan Stack task in the Startup Protocol, not shown, performs this task.)

3 The top-most Process Plate is downstacked from deck location 4 to deck location 1.

By default, when the <auto-select> location is selected for a process plate task, the process plates are always placed or downstacked at deck location 1. If deck location 1 is occupied, the process plate will be placed or downstacked at the next-available location.

4 Tips are installed on the pipette head at deck location 6.

5 The robot aspirates solution from the Reservoir at deck location 9.

6 The robot dispenses the solution into the Process Plate at deck location 1.

7 The robot mixes the solution in the Process Plate at deck location 1.

8 The pipette tips are removed at the Tip Box at deck location 6.

9 The Process Plate at deck location 1 is upstacked to deck location 7.

10 Steps 1 through 8 is repeated for each Process Plate stacked at deck location 4.

Related information

For information about... | See... |

|---|---|

Adding devices | • Device user guide |

Adding tasks in a protocol | |

Scan Stack task | |

Downstack task | |

Microplate-handling tasks | |

Liquid-handling tasks | |

Scheduling tasks |