Potential safety hazards

About this topic

This topic contains precautions about potential hazards that are specific to the BenchCel Microplate Handler. In addition to the following potential hazards, make sure that you understand how to avoid the general hazards described in the Automation Solutions Products General Safety Guide.

The potential hazards that you can encounter when using the BenchCel Microplate Handler include the following:

Moving parts

To minimize potential injury, the BenchCel device is designed to stop immediately if the robot head hits an obstacle while it is in operation. However, be aware that the robot moves with considerable force in the vertical or z‑axis direction and could pierce your skin with one of its grippers.

Not all circumstances can be foreseen and serious injury is possible. It is the responsibility of every operator to follow warnings and safety labels and keep out of the robot’s workspace whenever it is likely to move.

The BenchCel Microplate Handler has moving parts that can injure you if you deviate from the procedures given in this guide. Keep your fingers, hair, clothing, and jewelry away from the BenchCel Microplate Handler while it is in motion.

To avoid potential injury, do not touch the BenchCel Microplate Handler as you start the software. The robot head moves when the device initializes.

Never touch any of the moving parts or attempt to remove or add labware while the BenchCel Microplate Handler is in operation. The robot head moves with considerable force and can cause pinching, piercing, or bruising injury if you are in the path of the robot head or gripper.

Sharp edges and pinch hazards

Pinch hazard! Keep your fingers out of the path of the labware racks when you mount the racks on the BenchCel device.

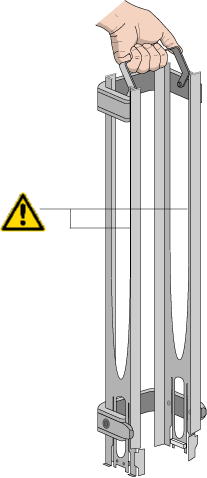

Use the rack handle to carry the labware racks. Do not hold a rack by the interior edges. The interior edges might have sharp surfaces that could cause cuts if handled improperly.

Figure Sharp surfaces on labware rack

Infrared LED injury hazard

Do not stare directly at the light-emitting diodes (LEDs) inside the stacker heads when the device is on. Such exposure to the LEDs can cause eye injury.

Each BenchCel stacker head contains seven infrared LEDs that detect the presence of a labware rack, microplates, and microplate notches. The LEDs are capable of dissipating 100 mW of power. Do not stare directly at the LEDs when the BenchCel Microplate Handler is turned on.

Static electricity

The rack-release button at the top of the stacker head on the BenchCel device is sensitive to static electricity. Static electricity can cause a potential loss of motor control and loss of communication with the BenchCel device. Ensure that you discharge any potential static electricity before touching the rack-release button. To discharge static electricity, you can touch the white painted or metal surface of the BenchCel device before touching the rack-release button.

Improper access or use

Improper use by an untrained user could damage the BenchCel Microplate Handler. For example, the robot gripper could collide with a stacker if a teachpoint is not defined properly.

Ensure that only fully trained BenchCel administrators have access to the user account passwords.

Lifting hazard

The BenchCel device without labware racks weighs 28 – 51 kg (61.7 – 112.4 lb), depending on the configuration. Attempting to lift or move the BenchCel device without assistance could cause personal injury. Request assistance and use proper lifting techniques when lifting or moving the device.

If the BenchCel Microplate Handler is incorrectly packaged and moved by someone other than an Agilent employee, the device may be damaged. Such damage is not covered by the warranty.

Before moving a BenchCel Microplate Handler, ensure the new location meets the laboratory requirements.

Related information