Setting BenchCel properties

About the BenchCel properties

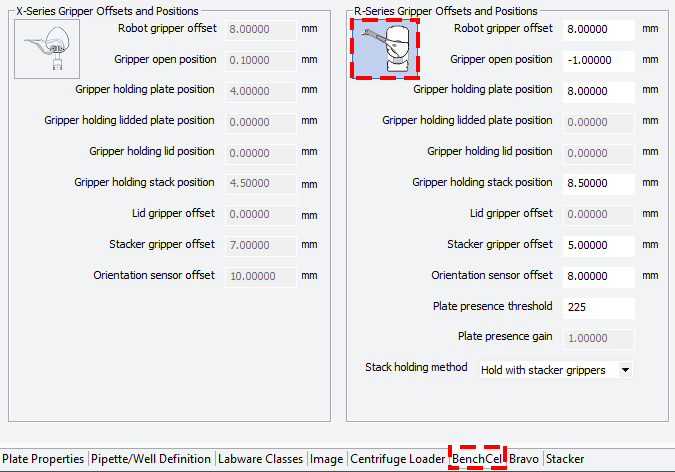

The BenchCel Microplate Handler X-Series and R-Series each have their own gripper offsets and positions. When you add a new labware entry, default parameter values are automatically inserted for both series. These values are approximate and should be ignored because the labware you are defining may be different.

Any labware that you are using with the X-Series must be redefined to work with the R-Series BenchCel Microplate Handler because the parameter values are different for the same piece of labware.

Note: You must also define a subset of the Stacker properties (under the Stacker sub-tab) because they apply to the built-in stackers of the BenchCel Microplate Handler.

Before you start

• You must be logged in as an administrator or technician to perform this procedure.

• You must first create an entry for the labware.

• VWorks Plus only. Each labware entry is a record of interest that transitions through development states. A VWorks technician or administrator can edit labware entries that are In Development or In Validation. The parameter settings in the Labware Entries tab are unavailable if the labware entry is Released.

Procedure

To define the BenchCel properties:

1 Open the Labware Editor.

2 In the Labware Entries tab, click the BenchCel sub-tab.

Figure BenchCel sub-tab

|

3 Click the button that corresponds to the BenchCel Microplate Handler type that is currently operating and for which you are defining the labware.

4 Measure the labware and enter the values for the following fields.

Parameter | Description |

|---|---|

Robot gripper offset (mm) | The distance from the bottom of a microplate to where the robot grippers will hold the microplate. |

Gripper open position (mm) | The distance the grippers move from the home position as the robot releases a microplate. A larger value moves the grippers closer together. A smaller value opens the grippers wider. Set this to –1 for R series and 0.1 for X Series BenchCel Microplate Handlers. |

Gripper holding plate position (mm) | The distance that the grippers move inward from their home position when holding a microplate that is not in a stack. A larger value moves the grippers closer together and holds the microplate tighter. A smaller value opens the grippers wider. Note: How tightly the robot grippers should hold a microplate depends on the microplate material and design. You might want to run some tests to optimize the parameter. |

Gripper holding lidded plate position (mm) | The distance that the grippers move inward from home position when holding a lidded microplate. An increasing value moves the grippers closer together and holds the lidded microplate tighter. A decreasing value opens the grippers wider. |

Gripper holding lid position (mm) | The distance the grippers move inward from home position when holding a microplate lid. Increasing the value moves the grippers closer together and holds the lid tighter. Decreasing the value opens the grippers wider. In general, type a value that is less than Gripper holding plate position to open the grippers slightly. Holding the lid too tightly might cause the microplate to be lifted with the lid. |

Gripper holding stack position (mm) | The distance the grippers move inward from the home position when holding a microplate that is in a stack. A larger value moves the grippers closer together and holds the microplate tighter. A smaller value opens the grippers wider. Note: Because the weight of the entire stack will be on the robot grippers, you should use a value greater than the Gripper holding plate parameter. |

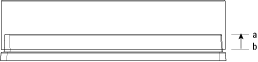

Lid gripper offset (mm) | The height (a) above the lid resting height (b) at which the gripper can grip the lid.  |

Stacker gripper offset (mm) | The distance from the bottom of a microplate to where the stacker grippers will hold the microplate. Be careful not to grab the microplate on the top edge of the skirt where the stacker grippers could slip onto the microplate body. Change this value only if the stacker is not gripping the microplates correctly. |

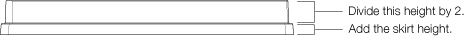

Orientation sensor offset (mm) | The distance from the bottom of a microplate to where the orientation sensors will check for notches. You can calculate the initial offset as follows: Determine the halfway distance between the top of the microplate and the top of the microplate skirt, and then add the height of the skirt.  See the BenchCel Microplate Handler User Guide for details on how to determine the optimum Orientation sensor offset. |

Stack holding method | R‑Series only. The option that specifies how the stacker holds the stack of microplates: • Hold with stacker gripper. For the greatest precision, select this method, for example, if your microplate has a narrow gripping tolerance requiring a specific stacker gripper offset. Holding the stack with grippers results in slower cycle time than the Hold with shelf method. • Hold with shelf. For faster cycle time, select this method if your microplate has a wider gripping tolerance and does not require a specific stacker gripper offset. |

Related information

For information about... | See... |

|---|---|

Using the Labware Editor | |

Workflow for adding labware to the Labware Editor | |

Opening the Labware Editor | |

Setting general properties for labware |