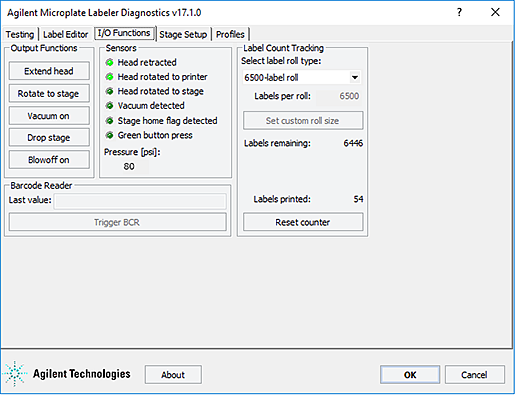

I/O Functions tab

About this topic

This topic provides a quick reference to the controls and indicators in the Microplate Labeler Diagnostics—I/O Functions tab. The controls and indicators in the I/O Functions tab are used primarily for verifying the correct functioning of the applicator and for troubleshooting problems.

Figure I/O Functions tab

|

I/O Functions tab procedures

The I/O Functions tab enables you to:

Procedure | See... |

|---|---|

Extend or retract the applicator head | |

Rotate the applicator head to the plate stage and back to the printer | |

Turn the vacuum on and off | |

Move the plate stage from the top position to the bottom position and back | |

Turn on and off the blowoff air | |

Check the regulated air pressure | |

Reset the labels printed counter to track the labels used per roll | |

Trigger the barcode reader |

I/O Functions tab contents

The I/O Functions tab contains the following:

• Output Functions area

• Sensors area

• Label Count Tracking area

• Barcode Reader area

Output Functions area

|

Controls and indicators | Description |

|---|---|

Extend head/Retract head | Extends or retracts the applicator head. |

Rotate to stage/Rotate to printer | Rotates the applicator head to the plate stage or to the printer. |

Vacuum on/Vacuum off | Turns on or off the vacuum to the vacuum pads on the applicator head. |

Drop stage/Raise stage | Moves the plate stage to the upper or lower stop position. |

Blowoff on/Blowoff off | Turns on or off the blowoff air to the applicator head. |

Sensors area

|

If a sensor indicator fails to light, the sensor might be faulty or require an adjustment. Contact Agilent Automation Solutions Technical Support for assistance.

Controls and indicators | Description |

|---|---|

Head retracted | Lights when the applicator head is in the retracted position (away from the printer). |

Head rotated to the printer | Lights when the applicator head is rotated to the printer. |

Head rotated to stage | Lights when the applicator head is rotated toward the plate stage. |

Vacuum detected | Lights when the vacuum is turned on and the vacuum pads on the applicator head are holding a label. |

Stage home flag detected | Lights when the plate stage rotation sensor detects the home flag. The light should be lit when the plate stage moves counterclockwise from the home position and extinguished when the plate stage moves clockwise from the home position. Note: If the plate stage rotates a full revolution and the light does not change state, the sensor might be faulty. |

Green button press | Lights when the green button on the top of the device is pressed and held. |

Pressure (psi) | Indicates the current air pressure inside the Microplate Labeler after the pressure has been regulated by the internal pressure regulator. The readout should be 80 psi (0.55 MPa), minimum. • If the readout is <80 psi. Verify that the air source is supplying 80 psi (0.55 MPa), minimum. If the source is above 80 psi and the readout is below 80 psi, use the pressure regulator knob on the back of the applicator to increase the pressure. • If the readout is >87 psi. Use the pressure regulator knob on the back of the applicator to lower the pressure to 85 psi (0.58 MPa), maximum. For instructions on setting the air pressure, see Setting the air pressure. |

Label Count Tracking area

The Label Count Tracking settings are saved to the printer.

Controls and indicators | Description |

|---|---|

Select label roll type | Specifies the number of labels on the label roll. |

Labels per roll | Available only if you select Custom roll size from the Select label roll type list. Allows you to set a roll size other than the standard sizes available in the list. |

Set custom roll size | Available only if the Custom roll size option is selected. Applies the value entered in the Labels per roll box. |

Labels remaining and Labels printed | Specifies labels remaining and the labels printed since the counter was reset. The labels remaining and labels printed typically equal the labels per roll. |

Reset counter | Resets the label counter so that the Labels printed field indicates 0. Click Reset counter when you load a new roll of labels. |

Barcode Reader area

|

Controls and indicators | Description |

|---|---|

Last value | Indicates the value read by the barcode reader. |

Trigger BCR | Available only if barcode reader is installed and initialized. Causes the barcode reader to scan the label of the microplate on the plate stage, and then displays the reading in the Last value box. |

Related information

For information about... | See... |

|---|---|

Opening Microplate Labeler Diagnostics | |

Other tabs in Microplate Labeler Diagnostics | |

Plate stage positions |