Centrifuge Process

Description

The Centrifuge Process task for the Centrifuge ( ) and the Centrifuge with Loader (

) and the Centrifuge with Loader ( ) indicates the start of a protocol subroutine that employs the Microplate Centrifuge (or Centrifuge). Within the subprocess, the software automatically adds the (

) indicates the start of a protocol subroutine that employs the Microplate Centrifuge (or Centrifuge). Within the subprocess, the software automatically adds the ( ) task to spin microplates according to the task parameter settings.

) task to spin microplates according to the task parameter settings.

) and the Centrifuge with Loader (

) and the Centrifuge with Loader ( ) indicates the start of a protocol subroutine that employs the Microplate Centrifuge (or Centrifuge). Within the subprocess, the software automatically adds the (

) indicates the start of a protocol subroutine that employs the Microplate Centrifuge (or Centrifuge). Within the subprocess, the software automatically adds the ( ) task to spin microplates according to the task parameter settings.

) task to spin microplates according to the task parameter settings. |

One microplate with a counterweight or two microplates can be spun at one time. Counterweights can be placed manually or robotically.

Task is available for... | Task is available in... |

|---|---|

Centrifuge, or Centrifuge with Loader | Main Protocol |

Task parameters

You set parameters for:

• Centrifuge Process. Contains the counterweight position information. For more information, see Centrifuge Process.

• Centrifuge task. Contains the spin parameters and counterweight selections. For more information, see Centrifuge.

Centrifuge Process

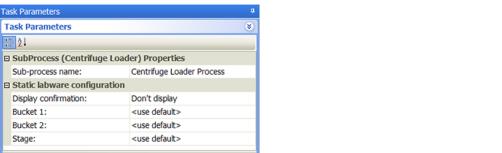

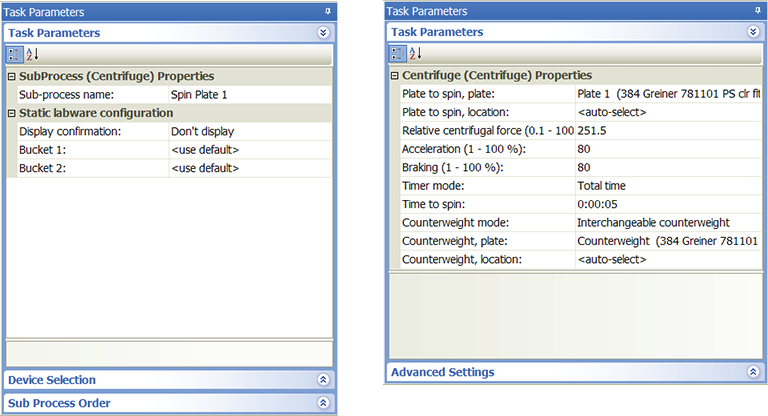

After you add the Centrifuge Process task (subprocess) at the desired point in the protocol, select the subprocess icon and set the following parameters in the Task Parameters area:

|

Parameter | Description |

|---|---|

Sub-process name | The name of the subprocess. Select from the list of available subprocesses currently in the protocol. |

Display confirmation | The option to display a message at the beginning of the protocol run to remind you to verify the physical locations of the labware match what you specified in the software. |

Bucket 1/Bucket 2 | The counterweight you want to use in the bucket location. You can select from the list of labware for either Bucket 1 or Bucket 2. The counterweight selection depends on the counterweight mode you select in the Centrifuge task: • If you are using the Interchangeable counterweight or Use 2 protocol plates counterweight mode, select <use default>. • If you are using the Fixed Counterweight mode, select a labware for either Bucket 1 or Bucket 2. For a description of the counterweight modes, see Centrifuge. |

Stage (Centrifuge with Loader only) | The stage at the Centrifuge Loader. |

Centrifuge

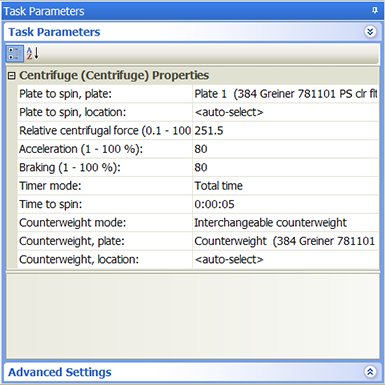

When you add the Centrifuge Process task (subprocess) at the desired point in the protocol, the Centrifuge task is automatically added. Select the Centrifuge task and set the following parameters in the Task Parameters area:

|

Parameter | Description |

|---|---|

Plate to spin, plate | The microplate that will be spun. Note: Select the counterweight microplate only if you plan to use the Fixed counterweight mode. |

Plate to spin, location | The device location to use. For example, you can select a centrifuge bucket. <auto-select> automatically places the labware at the first-available or appropriate location for the task. Make sure the Plate to spin, location selection does not conflict with the Counterweight, location selection. |

Relative centrifugal force (0.1–1006.2 × g) | The rotor velocity, as a multiple of gravity. |

Acceleration (1–100%) | The rate of centrifugation, as a percent of maximum acceleration. |

Braking (1–100%) | The deceleration of the centrifuge, as a percent of maximum deceleration. |

Timer mode | How the specified spin time is implemented: • Total time. The specified spin time includes acceleration and braking. • Time at speed. The specified spin time does not include acceleration and braking. |

Time to spin | The length of time to spin the microplates in the desired mode. |

Counterweight mode | The counterweight method used. Select one of the following: • Fixed counterweight. The counterweight is manually placed in the centrifuge before starting the run. The counterweight remains in the centrifuge during the entire run. You must remember to place the counterweight in the device before the run and remove it after the run is finished. • Interchangeable counterweight. The counterweight is on a platepad or in the Labware MiniHub. The robot will move it into the centrifuge during the run and return it to the platepad when the run is finished. If you select this mode, use the Counterweight, plate parameter to select the counterweight you want to use. • Use 2 protocol plates. Instead of a counterweight, a second process plate is used during the run. You must process two or more microplates in this mode. During the run, the robot places the first two microplates into the centrifuge. After spinning, the robot replaces the two microplates with the next pair, and so on. If you are processing an odd number of microplates, and three microplates are remaining, the robot will not remove the second from the last microplate so that the last microplate is paired. If you are processing an odd number of microplates, and: – A process contains only one Centrifuge Process task and it uses this counterweight mode, set the Simultaneous plate parameter to 2. – A process contains two or more Centrifuge Process tasks, and they all use this counterweight mode, set the Simultaneous plates parameter to 3 or greater. |

Counterweight, plate | The microplate or labware you want to use as the counterweight. This parameter is only available if you selected the Interchangeable counterweight method. If the list of counterweights do not appear, make sure: • You have added a device such as the Platepad for the counterweight. See Adding devices for instructions. • You have configured the labware correctly. See Configuring labware for instructions. |

Counterweight, location | The device location to use. For example, you can select a centrifuge bucket. <auto-select> automatically places the labware at the first-available or appropriate location for the task. Make sure the Counterweight, location selection does not conflict with the Plate to spin, location selection. |

Device selection

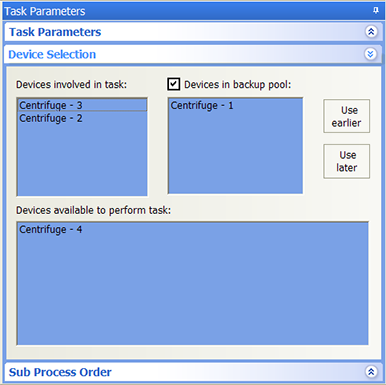

You must select a device for Centrifuge Process tasks. If you have multiple devices of the same type, you can:

• Prioritize the list of devices for the task. If the first device in the list is busy, the software will automatically use the next device in the list. If all of the devices in the list are busy, the task that needs the device will wait until one becomes available.

• Set up a backup pool. If the primary device encounters an error, the software will automatically use the next device in the list. However, if all of the devices in the list are in an error state, the software will automatically use the device in the backup pool.

After adding the Centrifuge Process task at the desired point in the protocol, select the task, and then click Device Selection in the Task Parameters area.

To select a device for the task:

1 Double-click the desired device in the Devices available to perform task area to move it to the Devices involved in task area. If you have multiple devices of the same type, you can move them to the Devices involved in task area.

2 If you have multiple devices in the Devices involved in task area, select a device, and then click Use earlier or Use later to prioritize it.

3 Optional. Select backup devices to use in case the primary device in the Devices involved in task area encounters an error.

a Select Devices in backup pool.

b Drag one or more devices from the Devices available to perform task area to the Devices in backup pool area.

c If you have multiple devices in the backup pool, select a device in the Devices in backup pool area, and then click Use earlier or Use later to prioritize it.

|

Subprocess order

If more than one subprocess uses the same configured labware, and the subprocesses are in different protocol processes, you can specify the sequence in which the subprocesses will be performed.

To specify the sequence in which the subprocesses will be performed on the same configured labware:

1 In the protocol process, select the sub-process that contains the task that uses the configured labware.

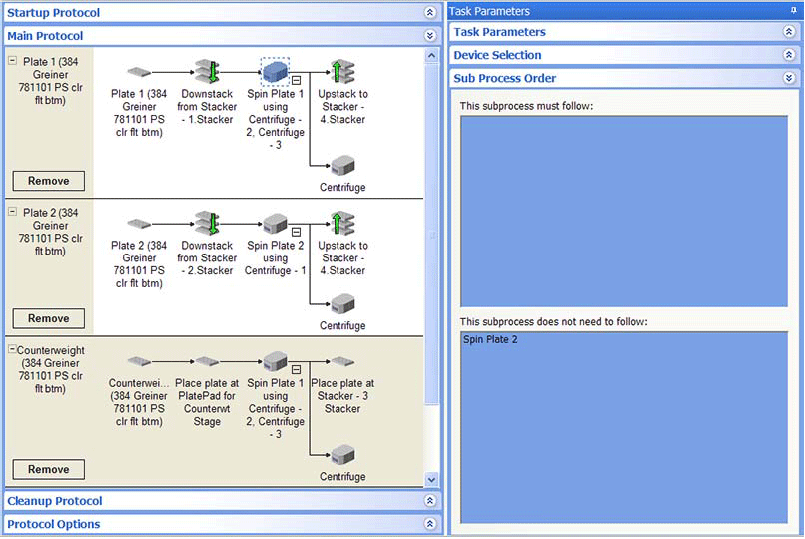

In the following example, the Spin Plate 1 process is selected.

|

2 In the Task Parameters area, click Sub Process Order.

3 In the Sub Process Order area, double-click the subprocess names to rearrange the order.

In the example shown in step 1, the order is Spin Plate 1 and Spin Plate 2.

Example: Interchangeable counterweight mode

Goal

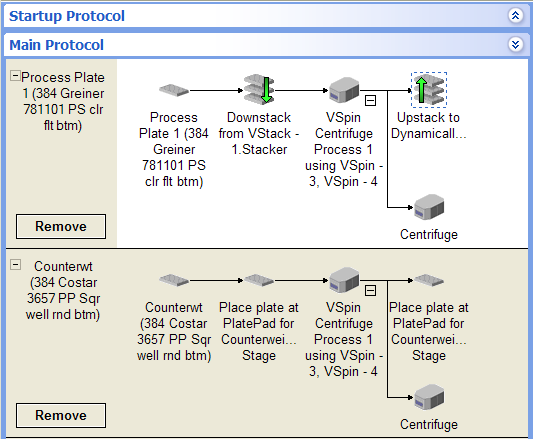

Downstack microplates from a BenchCel stacker, spin the microplates in the Microplate Centrifuge, and then upstack the microplates to an available BenchCel stacker. Use the counterweight that is stored on a designated platepad.

Implementation

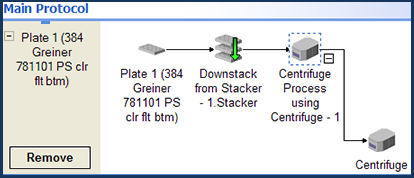

(1) Add a process for microplates that will be downstacked, spun, and upstacked. Add a Downstack, Centrifuge Process, and Upstack task in the order shown. (2) Configure the counterweight on a platepad and call it Counterweight.

|

The task parameters for the Centrifuge Process and the Centrifuge task are shown. Notice that the Bucket n parameters are set to <use default>, because the Interchangeable counterweight mode is selected.

|

Because the robot will move the counterweight from the designated platepad to the centrifuge during the run, select the Interchangeable counterweight mode. For the Counterweight, plate parameter, select Counterweight.

Note: The robot will move the counterweight back to the platepad when the run is finished.

Related information

For information about... | See... |

|---|---|

Adding devices | • Device user guide |

Adding tasks in a protocol | |

Configuring labware | |

Microplate-storage tasks | |

Liquid-handling tasks | |

Scheduling tasks |