AM Wash Syringes (Agilent Bravo)

Description

The AM Wash Syringes (Agilent Bravo) ( ) task enables the following types of washes using the Bravo 96AM Head:

) task enables the following types of washes using the Bravo 96AM Head:

) task enables the following types of washes using the Bravo 96AM Head:

) task enables the following types of washes using the Bravo 96AM Head:• Internal washing of the Bravo 96AM Head syringes

• External washing of the syringe probes

• External washing of the AssayMAP Bravo cartridges while mounted on the probes

Task is available for... | Task is available in... |

|---|---|

Bravo Platform with a Bravo 96AM Head and an autofilling station | Main Protocol, Bravo Subprocess |

Requirements

In Bravo Diagnostics, ensure that the 96AM Wash Station is set up at the correct deck location and associated with a Pump Module.

Ensure that the protocol has a configured labware for the 96AM Wash Station in addition to the other processes and configured labware required by the protocol.

Task parameters

After adding the AM Wash Syringes task at the desired point in the protocol, you set the parameters in the Task Parameters area.

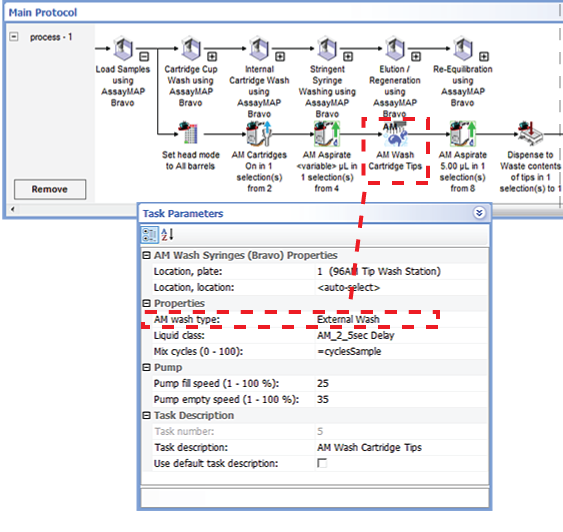

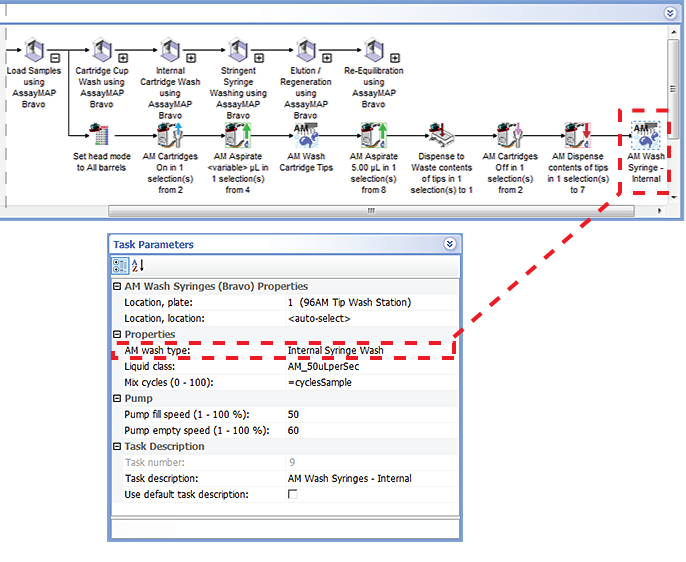

The software automatically selects all the chimneys in the wash station (entire plate) for the well selection and sets the volume and other properties. The following figure shows the AM wash type parameter: (A) External Wash or (B) Internal Syringe Wash.

|

The task actions vary depending on what you select for the AM wash type parameter:

• External Wash. Moves the tips of the probes or cartridges into the 96AM Wash Station chimneys. This wash type does not aspirate or dispense any volume. The liquid class can be used to control the duration of the wash.

Select the External Wash to wash the tips of the syringe probes or the cartridges mounted on the probes. See Example External Wash.

• Internal Syringe Wash. Dispenses to waste any contents remaining in the syringes, and then aspirates 250‑µL wash liquid from the 96AM Wash Station chimneys into the syringes. The task dispenses the 250‑µL volume to waste outside the chimneys, and then performs a tip touch on the chimneys’ exterior.

Select the Internal Syringe Wash to flush the syringe barrels with wash liquid. See Example Internal Syringe Wash.

For each wash you select the following parameters.

Parameter | Description |

|---|---|

Location, plate | The labware involved in the AM Wash Syringes task. Ensure that you use a 96AM Wash Station. |

Location, location | The location at which the AM Wash Syringes task occurs. <auto-select> The software uses the accessory configuration information in Bravo Diagnostics to determine the correct location for the task. This should be the deck location where the 96AM Wash Station is installed. |

AM wash type | The type of wash: External Wash (default) or Internal Syringe Wash. |

Liquid class | The liquid class for this wash liquid. Note: Although the External Wash does not include aspirate and dispense actions, you can use a liquid class with a delay to control the duration of the wash. |

Mix cycles (0–100) | Internal Syringe Wash only. The number of times to repeat the aspirate-and-dispense cycle for the wash task. Each mix cycle consists of one aspirate action and one dispense action. |

Pump fill speed (%) | The speed, in percent of maximum, at which liquid flows into the 96AM Wash Station inlet ports and up into the chimneys. The Pump fill speed should be fast enough for the wash liquid to just bubble over the tops of the chimneys. Initially, you should use the following values, and then determine if you need to make adjustments: • External Wash – Pump fill speed 25% – Pump empty speed 35% • Internal Syringe Wash – Pump fill speed 50% – Pump empty speed 60% |

Pump empty speed (%) | The speed, in percent of maximum, at which the waste liquid is pumped out of the 96AM Wash Station outlet ports. You should use the default values initially, and then determine if you need to adjust the value. |

Use default task description | The option to change the label that appears with the task icon in the Main Protocol area. • To use the default text, ensure that the check box is selected. • To create your own label, clear the check box, and then type the desired text in the field next to Task description. |

Example External Wash

Goal

After aspirating samples or other reagents through the AssayMAP cartridges, perform an External Wash to remove the residual liquid that can cling to the external surfaces of the cartridges and prevent carryover to future steps.

Implementation

In the following example, the configured wash station at deck location 1 is called 96AM Tip Wash Station. In the Load Samples subprocess, an External Wash (AM Wash Cartridge Tips) task is added between an AM Aspirate task to load the sample on the mounted cartridges and an AM Aspirate task that aspirates 5 µL buffer as a sample chase. In the External Wash parameter settings, the liquid class specifies a delay that defines the time duration that the tips remain in the chimneys.

Figure External Wash example in an AssayMAP subprocess to load samples

I

|

Example Internal Syringe Wash

Goal

After aspirating samples or other reagents through the AssayMAP cartridges and into the syringes, eject the cartridges, and perform an Internal Syringe Wash to remove unwanted residual reagents from the syringes.

Implementation

In the following example, the configured wash station at deck location 1 is called 96AM Tip Wash Station. In the Load Samples subprocess, an Internal Syringe Wash task is added at the end of the subprocess after the cartridges are removed at deck location 2 and the syringe contents have been dispensed for collection at deck location 7.

Note: The Internal Syringe Wash dispenses to waste any contents remaining in the syringes when the task begins.

Figure Internal Syringe Wash example in an AssayMAP subprocess to load samples

I

|

Related information

For information about... | See... |

|---|---|

Using the Bravo 96AM Head | AssayMAP Bravo Platform Getting Started Guide |

AM Aspirate task | |

AM Dispense task | |

Aspirate task | |

Dispense task | |

AM Cartridges On | |

AM Cartridges Off | |

Task macros | |

Protocol forms | |

Using JavaScript variables |