Overview for setting sensor thresholds

About this topic

You must set the Plate-presence and Orientation thresholds correctly for the specific type of labware you are using to ensure proper operation. For example, the thresholds must be accurate to ensure proper upstacking and downstacking of the labware. You must set the thresholds for the labware type before using the labware in a BenchCel protocol run.

This topic explains how the plate-orientation senors work and the workflow for setting the sensor thresholds.

How the plate-orientation sensors work

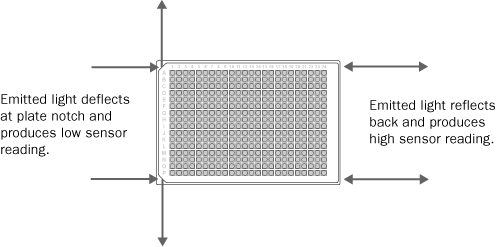

Four plate-orientation sensors on the inside wall of the stacker head detect the presence of microplate notches when the microplate is downstacked. Each sensor contains a light emitter that transmits light, and a receiver that reads the amount of light reflected by the surface of the microplate.

If the light beam bounces off of a wall that is perpendicular to its path, most of the light will reflect back. The resulting reading is relatively high. If the light beam bounces off of a wall that is not perpendicular to the light path, the light will be deflected. The resulting reading is significantly lower.

Figure Emitted light path on the notched and unnotched corners of a plate

|

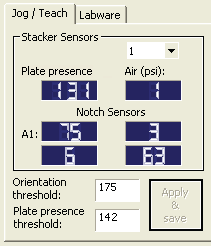

The amount of light that the sensor receives is displayed in BenchCel Diagnostics on the Controls page Jog/Teach tab. The microplate corners that have notches should have much lower readings than the corners that do not have notches. In the following example, the sensors detect a notch in the upper right and lower left corners of the microplate.

|

The following factors can affect the reading of the notch sensor and might require that you adjust the sensor light intensity:

• Microplate position. For optimum results, the sensor light should bounce off of the microplate at halfway between the top of the microplate and the top of the plate skirt.

• Microplate color. Darker microplate color might require higher light intensity.

• Microplate material. Shiny or reflective microplates might require lower light intensity.

• Microplate condition. Cracks, chips, scratches, or defects in the area where the sensor light contacts the microplate can affect sensor reading.

• Ambient light. Brighter rooms might require lower light intensity.

Workflow for setting sensor thresholds

Before you start

Make sure you have three spare microplates for each BenchCel stacker head. For example, if the BenchCel Microplate Handler has six stacker heads, you should have 18 microplates.

Make a copy of the provided Worksheet for setting sensor thresholds. You can use it to record sensor readings and facilitate threshold calculations.

Workflow

Step | For this task… | See… |

|---|---|---|

1 | Calculate the Plate-presence threshold. | |

2 | Determine the optimum sensor offset at each stack. | |

3 | Calculate the Orientation threshold based on the observed Notch Sensors readings. |

Related information

For information about… | See… |

|---|---|

Worksheet for sensor thresholds | |

Automation-ready labware | |

Labware definitions and the Labware Editor | VWorks Automation Control Setup Guide |

Filling and emptying the labware racks |