Simulating the protocol run

About run simulations

A protocol simulation is a virtual run where the software performs the tasks without moving robots or labware. Simulation runs are useful for troubleshooting scheduling and placement errors and optimizing throughput.

After checking for compiler errors, you can start a simulation to verify that tasks are completed and sequenced correctly. In addition, the simulation can help you find:

• Deadlocks

• Periods of inefficiency, such as when the robot is not being used

• Microplates spending different times at critical steps when they should be run under identical conditions

• A number of simultaneous plates that is too high or too low

Note: You can simulate the scheduling of multiple protocol runs, including those that run simultaneously.

Simulation time

The software uses the following lengths of time to simulate robot motions:

Robot movement | Time (sec) | |

|---|---|---|

BenchCel robot | Slow Medium Fast | 16 10 4 |

Phantom Robot | Slow Medium Fast | 16 10 4 |

Task | Specified in the task Advanced Settings area. The default value is 5.0. | |

Note:

• The BenchCel robot movement times are averages and might be conservative. The robot might take more or less time during a real protocol run.

• When using the Phantom Robot in a simulation, the software does not prompt the operator to move labware. Instead, the software uses the simulation time shown in the table.

You can override the default task simulation time in two ways:

• Perform a number of dry runs and allow the software to determine the average task time as it reaches a steady-state. The software then uses the average of the times during the subsequent simulation. See Optimizing simulation time.

• Manually set the desired task time in the Advanced Settings area of a task. See Setting desired task times.

Optimizing simulation time

To increase the accuracy of the run time, you can determine the optimum simulation time.

To determine the optimum task simulation time:

1 Start the simulation with the default task run times and the number of microplates expected for a run.

2 Resolve deadlocks and major errors in the protocol. Use the Gantt Chart to identify rate-limiting tasks and make adjustments to improve throughput. For instructions, see Tracking the run progress of instances or devices.

3 Turn off the simulation mode and perform a dry run with empty labware. Make sure the number of plate instances processed equals the number of simultaneous plates allowed. Doing so allows the run to reach a steady state and enables the software to update the task simulation times with actual times.

4 Save the protocol to save the updated task simulation times.

Setting desired task times

You can manually set task times to override the default task time or the optimized task time.

To set a desired task simulation time:

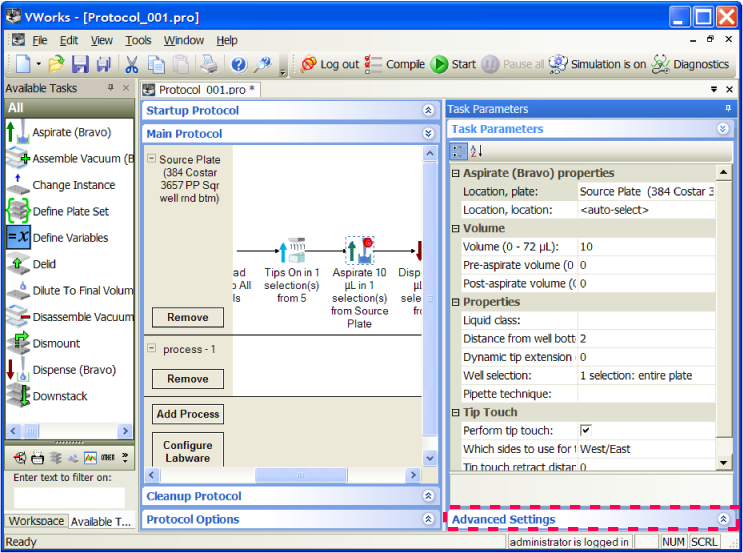

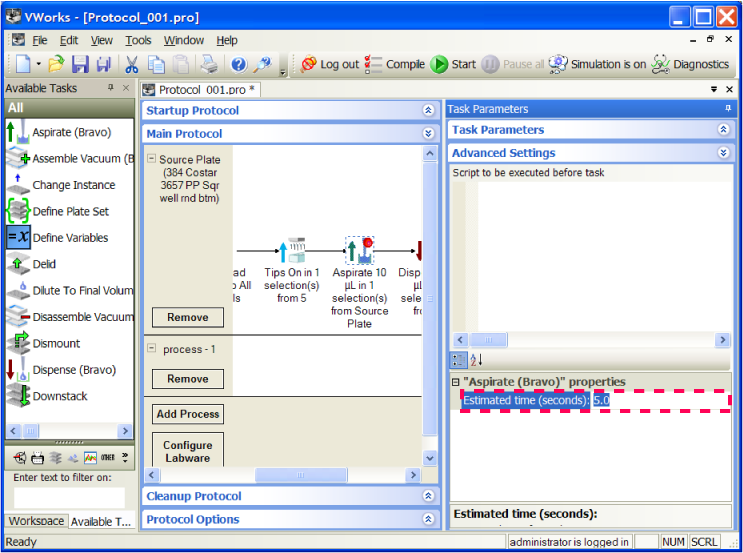

1 Select a task in the protocol.

2 In the Task Parameters area, click Advanced Settings.

|

3 At the bottom of the Advanced Settings area, view the existing value or type a new value for Estimated time for the selected task. To provide optimal simulation times, see Optimizing simulation time.

Note: Only some tasks have adjustable run times.

|

Running the simulator

To run the simulator:

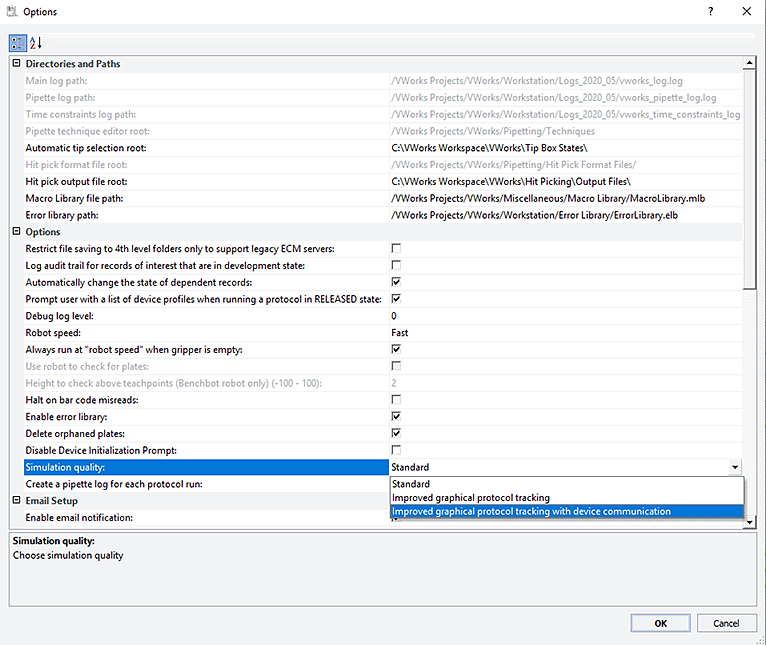

1 Select Tools > Options. In the Options dialog box, select the simulation quality you want to use:

|

Simulation quality | Description |

|---|---|

Standard | Protocol tracking (green dots) is close to accurate, but not exact. This option results in faster simulation, because certain physical constraints are not simulated. In addition, less time is devoted to refreshing the graphical user interface. |

Improved graphical protocol tracking | Protocol tracking is more accurate but results in longer simulation time than the Standard quality option. Similar to the Standard quality option, the software does not query the device plugins for physical constraints. However, the software ensures the green dots in the Protocol area are positioned accurately during the simulation. |

Improved graphical protocol tracking with device communication | Protocol tracking is the most accurate. The software queries the device plugins to ensure every move is physically permissible, resulting in a slower but more accurate simulation. |

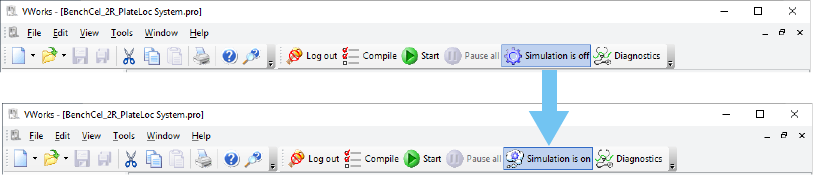

2 Turn on the simulation mode: Click Simulation is off on the toolbar. The button changes to Simulation is on.

|

3 Start the protocol run. See Starting the protocol run for the different ways you can start a run.

The simulation starts. The Run Configuration Wizard and other dialog boxes open as they would in a real protocol run. Follow the instructions in the dialog boxes to proceed with the simulation. For detailed information about Run Configuration Wizard, see Starting the protocol run.

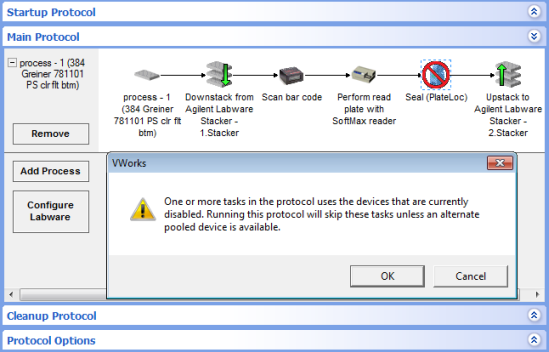

Simulating a run with a disabled device

When you run a protocol in simulation that contains tasks pointing to a disabled device, and no equivalent devices are available in the pool, the software displays a warning message and a  is displayed on the affected task.

is displayed on the affected task.

is displayed on the affected task.

is displayed on the affected task. |

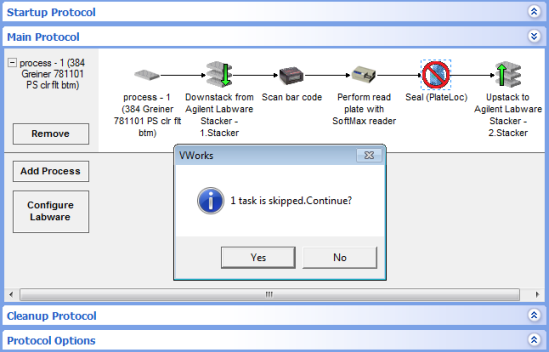

Click OK to run the protocol. The following dialog box appears indicating how many tasks will be skipped:

|

Click Yes. The Run Configuration Wizard opens. Follow the instructions in the wizard. For details on the wizard, see Starting the protocol run. During the run, the tasks associated with the disabled device are skipped.

Related information

For information about... | See... |

|---|---|

Compiling the protocol | |

Selecting simulation qualities | |

Changing the robot speed | |

Temporarily disabling a device in a device file | |

Scheduling multiple runs | |

Managing runsets | |

Monitoring runs | |

Pausing runs | |

Deadlock recovery |